The Rashid rover. Image credit: ESA/Mohammed Bin Rashid Space Centre

Disclaimer: The views expressed herein by the authors in no way reflect the official opinion of the European Space Agency.

Berlin, 27 January 2023 - Orion Additive Manufacturing, a Berlin-based startup focusing on developing advanced 3D printing systems, is on its way to the moon. Well, their prints are!

The European Space Agency (ESA) announced on January 12th that the very first European technology to make contact with the surface of the Moon will include 3D prints produced by Orion Additive Manufacturing (Orion AM).

These will also be the first 3D-printed parts on the moon. The samples are mounted on the wheels of the Rashid rover for the Emirates Lunar Mission’s “Material Adhesion and Abrasion Detection” experiment, which tests the resistance of different materials to the harsh lunar environment. The mission launched successfully on Sunday, December 11, 2022, and is expected to make first contact with the lunar surface in April 2023.

“[Orion AM] is particularly adept at 3D printing in PEEK, so the sample has ended up as high quality as possible.”

The 3D-printed samples were made from a conductive material with carbon nanotubes and graphene produced by ESA for potential use in space applications. For this mission, ESA materials engineer Dr. Ugo Lafont “selected a 3D printed sample of PEEK thermoplastic, short for ‘Polyether ether ketone’, which is robust enough to substitute for metal parts in some circumstances and is known to resist the space environment.” (ESA, 12.01.2023)

Although PEEK is notoriously difficult to print and typically results in mechanical properties much weaker than injection-molded parts, Orion AM’s proprietary 3D-printing process achieves mechanical properties even higher than injection molding.

In 2021, Orion AM began collaborating with the ESA’s European Space Research and Technology Centre (ESTEC) on the project that will now bring the first 3D-printed parts to land on the moon. The samples printed with ESA’s conductive PEEK for internal testing at ESA-ESTEC, resulted in mechanical properties up to 87% higher than previously achieved using a non-PEEK optimized 3D printing technology.

Conductive PEEK flexural tests performed at ESA-ESTEC. Image credit: ESA

Reference: Lafont, U. (2022, 18-23 September), Electrically conductive PEEK 3D printing from ground to space qualification. 15th International Symposium on Materials in the Space Environment, Leiden, The Netherlands

Seeking the best possible print quality, Dr. Lafont selected Orion Additive Manufacturing to manufacture ESA’s PEEK samples for the mission, citing that “this company is particularly adept at 3D printing in PEEK, so the sample has ended up as high quality as possible.” (ESA, 12.01.2023).

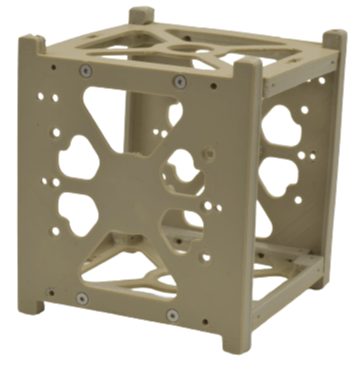

The 3D-printed components bonded to the Rashid rover’s wheels prior to launch. Image credit: ESA/MBRSC

The technology developed by Orion AM pushes the boundaries of the additive manufacturing of high-performance polymers, like PEEK, making the technology not only accessible but also feasible for serious aerospace applications.

“These unique and special materials, which are challenging to 3D print while maintaining their superior material properties, are exactly why we developed our A150 additive manufacturing system. Our system allows these materials to easily be processed into end-use and space-ready components, and function to their full potential regardless of loading direction or environment. We are very grateful to have been selected by ESA to contribute to this project.” says Adam Rumjahn, the managing director of Orion Additive Manufacturing. “We have developed this technology over the last 5 years, and are proud to announce this achievement - it is truly a dream come true to have 3D printed parts from Orion AM on the moon!”

The research team at Orion AM has also begun validating its claims with data related to its process. In multiple studies, Orion AM has proven that its technology is capable of consistently printing with near isotropy and even surpassing the injection-molding strength of several PEEK materials. These studies were done in collaboration with several of the largest PEEK material producers, who each performed independent testing on the samples provided by 3D printer manufacturers. One of these studies, the Solvay Printer Evaluation Programme (S-PEP), was recently updated with Orion’s A150 AM system listed as the best option for several of Solvay’s materials. Another study with Evonik and their PEEK materials showed that Orion AM’s process consistently achieved mechanical properties greater than injection molding. These achievements are beginning to make a significant impact on how the industry perceives polymer additive manufacturing.

“Our goal is to update material data sheets with 3D-printed data using Orion AM’s process so that the industry can be convinced that it is possible to 3D-print high-performance polymers without compromises,” adds Adam. “This will ultimately drive adoption of our additive manufacturing for end-use parts in the industry, in space, and in the medical sector as well”.

Learn more about Orion AM

Orion AM’s facilities. Image credit: Orion AM

Orion AM’s primary focus is the development of additive manufacturing solutions for 3D printing with high-performance polymers with applications in space and the medical sector. They strive to continue pushing the limits of additive manufacturing and hope that their next mission will be to Mars. To learn more about Orion AM, visit their website and LinkedIn page or write to them at info@orion-am.com.