Advanced Materials

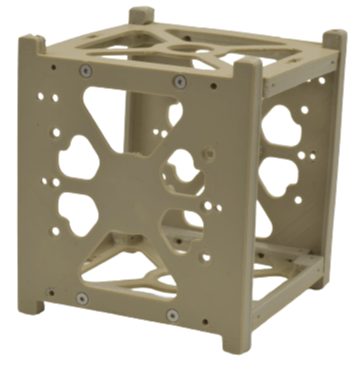

Superior mechanical strength. High thermal resistance. Chemical resistant. Exceptional dielectric strength.

These high-performance polymers for 3D printing are designed for the most demanding engineering applications. Orion AM has worked rigorously with material suppliers to validate our 3D printing process. The tensile strength data obtained were all produced independently by each material supplier and validated by a third-party accredited lab. The results prove that Orion AM's Thermal Radiation Heating process consistently achieves injection molding strength, irrespective of the grade or source of the material.

3rd-Party Tensile Strength Data

Industrial Grade PEEK Filaments

KetaSpire®

PEEK

Tensile Strength (MPa)

Injection Molding Strength: 91 MPa

INFINAM®

9359F

Tensile Strength (MPa)

Injection Molding Strength: 90 MPa

Victrex

AM™450FIL

Tensile Strength (MPa)

Injection Molding Strength: 98 MPa

LUVOCOM® 3F PEEK 9581 NT

Tensile Strength (MPa)

Injection Molding Strength: 95 MPa

KetaSpire®

PEEK CF

Tensile Strength (MPa)

Injection Molding Strength: 159 MPa

Medical/Implantable Grade PEEK Filaments

Invibio PEEK-OPTIMA® LT1

Tensile Strength (MPa)

Injection Molding Strength: 100 MPa

VESTAKEEP® PEEK i4 3DF

Tensile Strength (MPa)

Injection Molding Strength: 94 MPa

TECAFIL PEEK VX MT

Tensile Strength (MPa)

Injection Molding Strength: 100 MPa

Other High-Performance Polymers

Victrex

AM™200FIL

Tensile Strength (MPa)

Injection Molding Strength: 90 MPa

Radel®

PPSU

Tensile Strength (MPa)

Injection Molding Strength: 74 MPa

Material Properties

PEI

PEI or ULTEM™ has excellent strength, thermal stability, and meets FAR 25.853 and OSU 65/65 with low toxicity, smoke, and flame evolution.

ULTEM technical description:

Tensile Modulus: 2.15 GPa

PEEK

PEEK is as strong as metal and has excellent mechanical and thermal resistance up to 260 °C. This organic polymer is resistant to dissolving in oils and other substances, unlike most other plastics.

PEEK technical description:

Tensile Modulus: 4.0 GPa

PPSU

PPSU is a high-temperature, chemical-resistant polymer that provides a lower cost alternative to PEEK and ULTEM.

PPSU technical description:

Tensile Modulus: 2.1 GPa

PEEK Materials

PEEK (poly-ether-ether-ketone) is a high-strength, temperature-resistant, chemically resistant, inert thermoplastic used in various engineering applications, from aerospace and medical. It is also used as a lightweight substitute to replace metal parts for mass reduction.

Orion AM's patent-pending Thermal Radiation Heating technology helps get the most benefit from these material properties by increasing interlayer bonding and crystallinity. This results high strength parts for end-use applications.