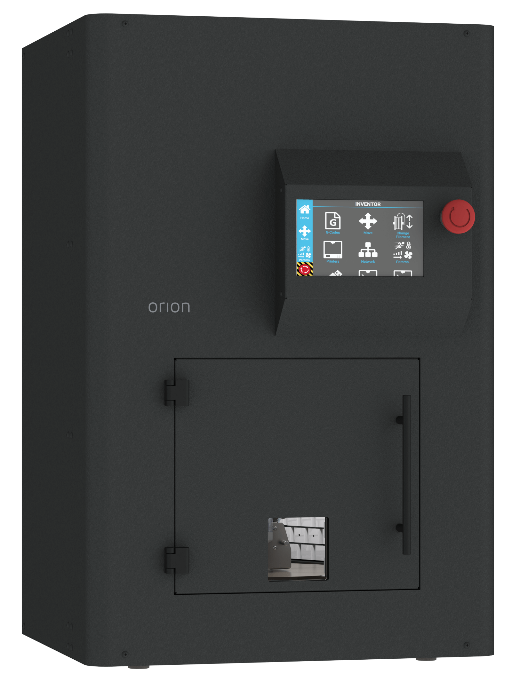

A150 Series

by Orion AM

An advanced industrial additive manufacturing system

for 3D printing high-performance polymers

with Thermal Radiation Heating

to achieve superior strength.

Discover

The Orion AM A-Series

An Industrial Additive Manufacturing System for 3D printing with high-performance polymers like PEEK, ULTEM and PPSU. The process utilizes the patent-pending Thermal Radiation Heating Technology developed by Orion AM to fuse the printed layers together. This results in industrial grade parts with nearly injection molding strength.

Tensile strength PEEK

Study - Z orientation

High temperature

Orion AM’s technology efficiently heats the print from all directions up to 300 °C, thus increasing the inter-layer bonding and improving mechanical strength.

High Performance

Engineered for Industrial Additive Manufacturing of parts with high performance polymers like PEEK, ULTEM, PPSU and more.

High Strength

Orion’s patent pending Thermal Radiation Heating technology enhances interlayer bonding at least 5x, achieving more uniform strength.

Reduce cost

Print up to 8x faster with less machinery, lower operating time and lower capital investment. Reduce waste and operating costs by 95% compared to SLS.

A new approach to AM

Overview

Fused Filament Fabrication (FFF) suffers from weak interlayer bonding, delamination and warping because the material cools down after being deposited. A heated chamber usually heats the air, but Orion AM's Thermal Radiation Heating heats the material!

Benefits

With Thermal Radiation the heat penetrates through the material, allowing the layers to truly fuse together. This results in parts that are more uniform in strength, more dense and stronger.

Results

Orion's technology resolves the anisotropic nature of FFF 3D printing, even for difficult to print aerospace-grade materials like PEEK and PEI. This results in nearly isotropic properties.

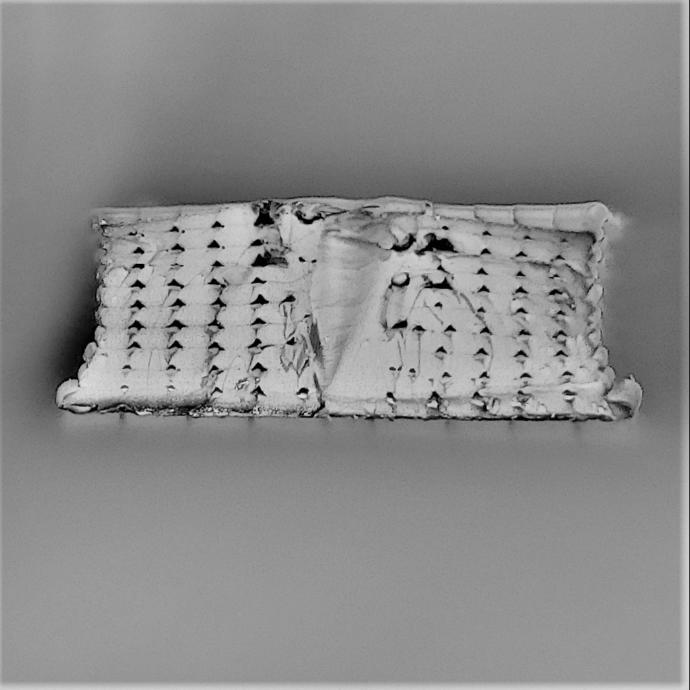

Without Thermal Radiation Heating

- Visible Layers

- Porous Structures

- Poor Interlayer Bonding

- Low Strength, Anisotropic

Suitable for Prototypes only!

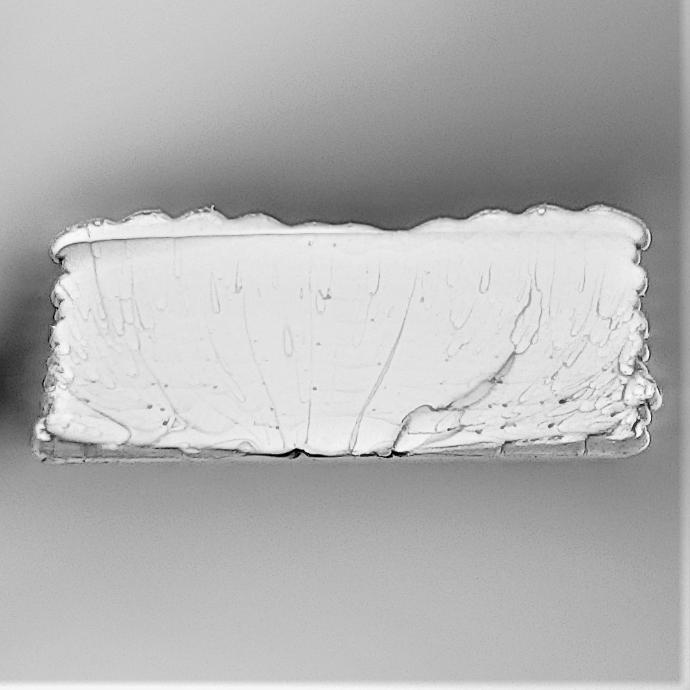

With Thermal Radiation Heating

- No Visible Layers

- Dense, Homogenous Structures

- Good Interlayer Bonding

- High Strength, Isotropic

Suitable for End-Use Production Parts!

Designed for Advanced Materials

Our Patent-Pending Thermal Radiation Heating technology gives you the most out of these advanced materials by thermally welding the printed layers together, making them more durable and usable as end-use parts.

Technical Specifications

| PRINTING |

|

| Build Volume: | 180mm diameter x 150mm high |

| Nozzle diameter(s): | 0.10mm - 0.40mm |

| Layer Height: | 20μm - 400μm |

| Print Speed: | 10mm/s - 400mm/s |

| Technology: | FFF - Thermal Radiation Fusion |

| Extruder Max Temp: | 500°C |

| Bed Max Temp: | 300°C |

| TRH* Max Temp: | 315°C Chamber Temperature, 370°C Layer Heater Temperature |

| Filament Diameter: | 1.75mm |

| Materials: | PEEK, PAEK, PEKK, PEI, ULTEM1010, ULTEM9085, ABS, PC, PA6, PA12, PPSF/PPSU |

| *TRH (Thermal Radiation Heating) involves using thermal radiation in all directions to efficiently heat the printed object up to 300°C | |

| CONNECTIVITY |

|

| WiFi: | ✓ |

| Ethernet: | ✓ |

| USB type B: | ✓ |

| USB stick: | ✓ |

| HARDWARE |

|

| Display: | 7" capacitive touchscreen display |

| Overall Dimensions: | 570mm x 550mm x 830mm |

| Weight: | 50kg |

| Motion Kinematics: | Delta 3-Axis platform |

| Voltage: | 380 - 440V AC |

| Power consumption: | 5kW Peak / 1kW Nominal |

For more information, download our A150 brochure