Orion Additive Manufacturing GmbH is a key partner in the AM-SPACE project, a groundbreaking initiative focused on developing advanced manufacturing processes for deployable, space-grade solar modules. This project, supported by the European Union's EFRE initiative, leverages Orion's expertise in 3D printing to contribute to its success.

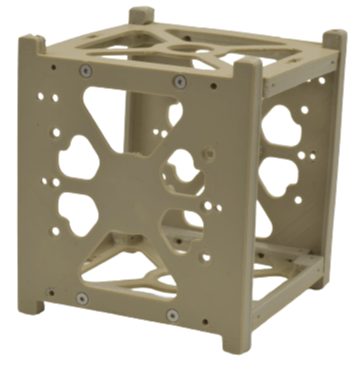

Launch of a rocket carrying small satellites, demonstrating the increasing need for efficient solar panels.

Launch of a rocket carrying small satellites, demonstrating the increasing need for efficient solar panels.

Over the next five to six years, the launch of small satellites is expected to surge, bringing unprecedented demand for efficient and reliable solar energy solutions. The AM-SPACE project addresses this need by replacing traditional, heavy metal hinges with innovative shape memory polymers that connect solar panels. These polymers allow solar panels to fold compactly and deploy seamlessly using thermal activation, while also being stiffer to facilitate faster satellite tracking.

Orion is pioneering the development of high-temperature resistant 3D printing systems capable of manufacturing composite materials that meet the rigorous demands of space applications. This technology will enable the production of ultra-thin, lightweight, and reliable solar arrays with integrated sensors, ensuring high energy output and durability.

Orion Additive Manufacturing GmbH is proud to collaborate with German Orbital Systems, Fraunhofer IZM, and Fraunhofer IAP in this consortium, combining collective expertise to push the boundaries of space technology. The project is co-funded by the European Union in the AMBER call with funding reference number 10193599.

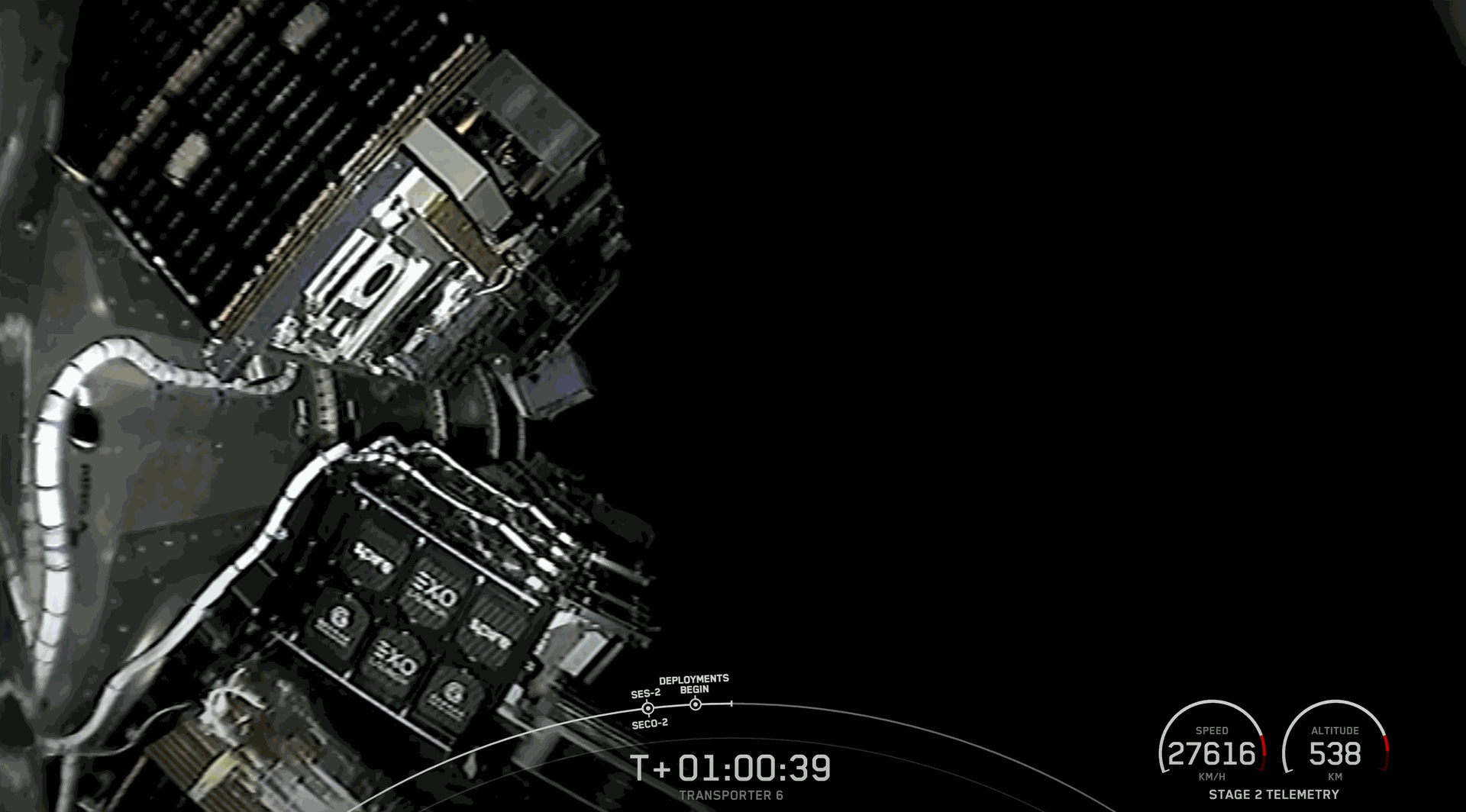

German Orbital Systems' satellites prepared for deployment inside a SpaceX launcher.

German Orbital Systems' satellites prepared for deployment inside a SpaceX launcher.

Stay connected with Orion Additive Manufacturing GmbH as it continues to push the boundaries of space technology and additive manufacturing. Follow the journey and learn more about contributions to the AM-SPACE project on social media channels and the website.

Together, these efforts are making space more accessible and efficient. 🚀