By Adam Rumjahn of Orion Additive Manufacturing GmbH & Lennart Zeller of Technische Universität Berlin

Introduction

The field of 3D printing has witnessed significant advancements in recent years, with continuous carbon fiber printing emerging as a promising technology for producing high-strength, lightweight components. A recent study conducted by Lennart Zeller of Technische Universität Berlin in collaboration with Orion Additive Manufacturing GmbH has shed light on the potential of this technology.

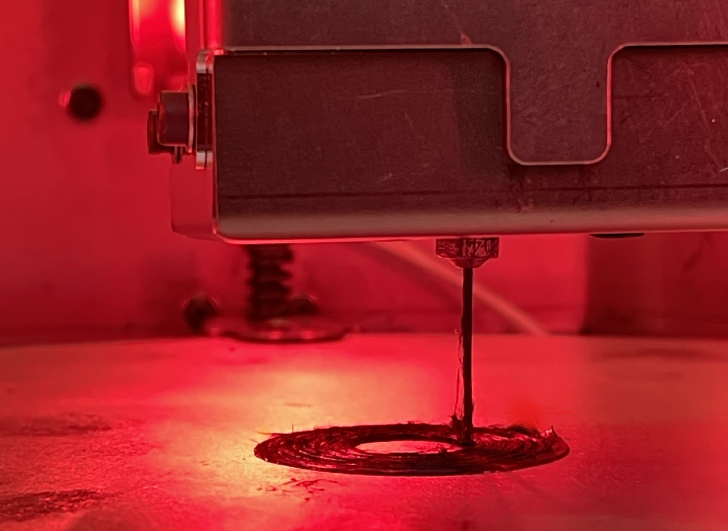

Orion's Process and Achievements

In the research conducted by Zeller and Orion, a material known as Filaprem CF/PEEK, supplied by Suprem, was used. Jacques Stadlin, Customer Project Engineer at Suprem, expressed his satisfaction with the results, stating, “We are very pleased to see the excellent results the Orion printing system is achieving with our continuous fibre reinforced thermoplastics. This confirms our vision of Filaprem™ contributing to the 3D printing technology and opening up some new exciting opportunities both technologies have to offer."

This material, when processed using Orion's Thermal Radiation Heating (TRH) technology, demonstrated remarkable mechanical properties. The table below provides a comparison of the mechanical properties of Filaprem CF/PEEK under different conditions, as well as the properties of Markforged's Carbon material.

Material | Tensile | Tensile | Tensile Elongation | Flexural | Flexural Modulus (GPa) | Flexural Elongation at break |

Suprem Filaprem | 1261 | 120⁽¹⁾⁽²⁾ | -⁽²⁾ | 621 | 113 | 0.6 |

Suprem Filaprem | 850 | 120⁽¹⁾⁽²⁾ | -⁽²⁾ | 501 | 96.5 | 0.6 |

Markforged Carbon | 800 | 60 | 1.5 | 540 | 51 | 0.7 |

⁽¹⁾ Filaprem CF/PEEK is expected to be between 80-120 GPa

⁽²⁾ Due to errors in measurement the tensile modulus and elongation data were omitted

The tensile strength of Filaprem CF/PEEK with TRH turned on is 57.6% higher than that of Markforged Carbon, and the flexural modulus is 121.6% higher. These results underscore the effectiveness of Orion's TRH technology in enhancing the mechanical properties of the printed material.

Image: Orion AM’s Process Printing Suprem Filaprem™ CFF PEEK with TRH

Image: Orion AM’s Process Printing Suprem Filaprem™ CFF PEEK with TRH

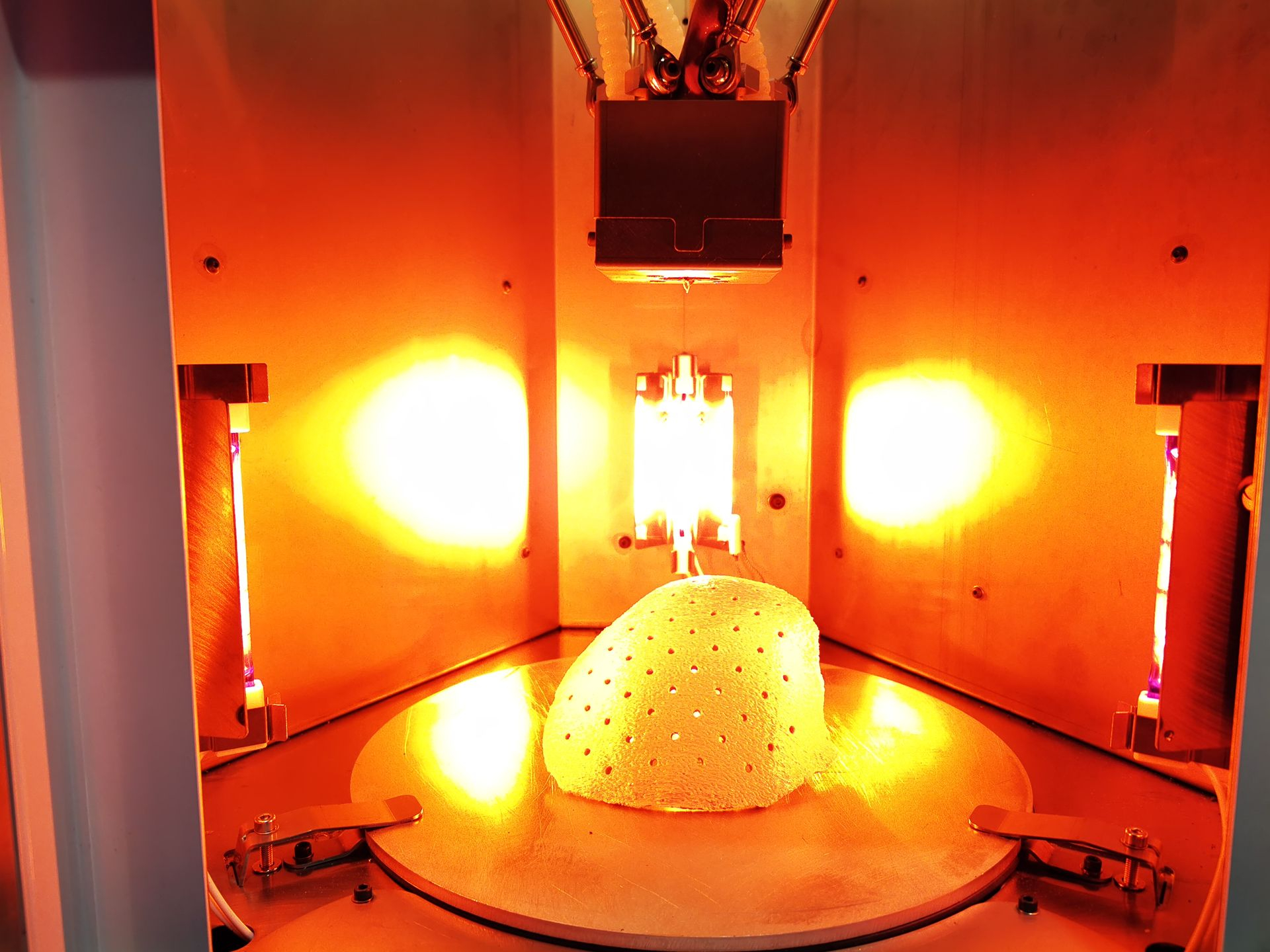

Challenges and Research in Continuous Carbon Fiber 3D-Printing

Continuous carbon fiber 3D printing presents several challenges, primarily related to the consolidation and bonding of the carbon fibers. The Continuous Filament Fabrication (CFF) process, which is a cold process, often leads to poor bonding between the layers, fiber, and matrix. This results in a high degree of porosity and voids, which can significantly reduce the material's mechanical properties. To achieve the properties of a true composite, much higher processing temperatures are required.

Image: Tensile Test Specimens Produced with Orion TRH Process

A study by Goh et al. (2020) highlights the complexity of the process-structure- properties relationship in polymer additive manufacturing¹. The study underscores the need for careful control of various parameters to achieve desired results. Similarly, a study by Li et al. (2019) discusses the challenges in additive manufacturing of fiber-reinforced polymer composites². The study emphasizes the importance of understanding the interplay between the printing parameters and the resulting mechanical properties of the printed material.

Markforged's Carbon material, while widely used in the industry, has been found to have relatively poor mechanical properties compared to other materials. This is largely due to the material's high degree of porosity and the presence of voids, which can significantly reduce its strength and stiffness. A study by Antonino Squillace (2021) investigated the effect of fiber orientation on the mechanical properties of composites produced using the Markforged continuous filament fabrication (CFF) technique³. The study found that the layer-by-layer print deposition process often results in voids between the layers, which can significantly reduce the material's strength.

Orion's Solution: Thermal Radiation Heating (TRH)

Orion's solution to these challenges is the use of Thermal Radiation Heating (TRH) in their continuous carbon fiber printing process. TRH significantly improves the consolidation and bonding of the carbon fibers, resulting in a material with much higher strength and stiffness. As shown in the table, the tensile strength of Filaprem CF/PEEK with TRH turned on is significantly higher than that of Markforged Carbon, reaching 1261 MPa compared to 800 MPa. This represents a 57.6% increase in tensile strength. Similarly, the flexural modulus of Filaprem CF/PEEK with TRH turned on is 113 GPa, more than twice the 51 GPa of Markforged Carbon, indicating a 121.6% increase in stiffness.

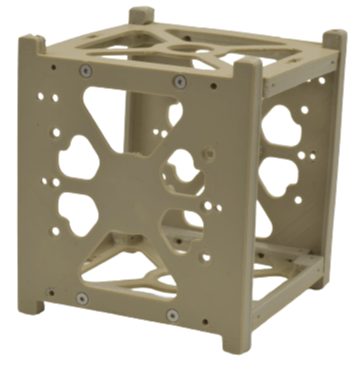

Image: Orion’s Additive Manufacturing System for PEEK

Image: Orion’s Additive Manufacturing System for PEEK

Implications and Applications

The superior mechanical properties achieved by Orion's process with TRH have significant implications for various industries. In the space industry, for example, the high strength and light weight of the materials produced by this process make them ideal for use in lightweight structures, sandwich panels, deployable solar arrays, and satellite structures.

In the medical field, the potential applications are equally exciting. Trauma plates, for instance, could benefit from the high strength and light weight of these materials. Furthermore, Suprem's sister company, icotec, already manufactures implants using carbon fiber. The ability to 3D print these implants using Orion's process could revolutionize medical device manufacturing. As stated on icotec's website, their implants are constructed from a unique manufacturing technology, offering unparalleled composite implants for the operative treatment of tumor diseases of the spine⁴.

Conclusion

The research conducted by Lennart Zeller and Orion Additive Manufacturing GmbH has demonstrated the significant potential of continuous carbon fiber 3D printing, particularly when combined with Thermal Radiation Heating (TRH). The superior mechanical properties achieved by this process open up exciting possibilities for various industries, from space to medical. As the field of additive manufacturing continues to evolve, Orion's contributions are likely to play a pivotal role in shaping its future.

* Click here to download this White Paper as a PDF

This white paper was prepared by Lennart Zeller, Technische Universität Berlin and Orion Additive Manufacturing GmbH. For more information, please contact Orion Additive Manufacturing GmbH, Berlin, Germany at info@orion-am.com.

References:

-

Goh, G. K. M., Yap, Y. C., Tan, H. H., Sing, S. L., & Yeong, W. Y. (2020). Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Critical Reviews in Solid State and Materials Sciences, 45(2), 113–133. https://doi.org/10.1080/10408436.2018.1549977 ↩

- Li, G., Yap, Y. C., Agarwala, S., & Yeong, W. Y. (2019). Recent Progress in Additive Manufacturing ofFiber Reinforced Polymer Composite. Advanced Materials Technologies, 4(1), 1800271. https://doi.org/10.1002/admt.201800271 ↩

- Squillace, A., Prisco, U., Astarita, A., & Nele, L. (2021). Effect of Fiber Orientation on Mechanical Properties of 3D Printed CF-PEEK Composites. Polymers, 13(15), 2524. https://doi.org/10.3390/polym13152524 ↩

- icotec AG. (2023). Carbon/PEEK Composite Implants. Retrieved from https://www.icotec-medical.com/en/ ↩